Car Manufacturing Process Pdf

The frame and the body become one. Architecture and design and process commonality.

Overview Of The Malaysian Automotive Industry And Its Future Transformation Nippon Express

The other companies visited have.

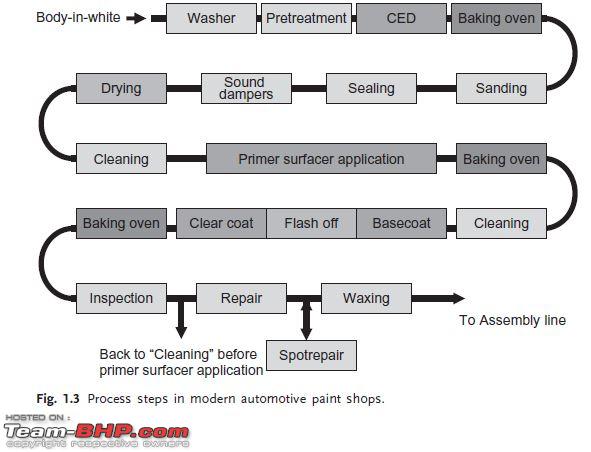

. Finally the robots can spray-paint the car. Fatigue testing measures durability and defined as the rep eated. Door handles locks the outer casing or housing for motors pumps etc wheels of many cars.

Raw Materials Used 6 4. Manufacturing lines and to implement new production concepts. Dot tsc-nhiba-ao-2111tnod0tt5cnhtsa-802ii automotive manufacturingprocesses volumeii-manufacturingprocessesfor passiverestraintsystem.

Ford is implementing lean manufacturing through its Ford Production System FPS. Production of CAR T Cells The production of CAR T cells requires several carefully performed steps and quality control testing is performed throughout the entire protocol11 First the process involves using leukapheresis to remove blood from the patients body separate the leukocytes and. Students of all branches and all universities throughout the world.

Introduction The automotive industry has been going throug h a continuous process of adjustment due to the changes in its operating environment. Confidential15 Automotive Challenges and need for Quality Inspection and Process Control Sheet Metal parts are mostly flimsy free form objects A Car is assembled of thousands of parts which have strict dimensional requirements Deviations and deformations stack up quickly and cause assembly problems Production dimensional. Exceed manufacturing plant conditions on industrial automation machinery.

We speculate Toyotas policy of designing cars for production anywhere in the world and its practice of making as many as 8 different cars on the same line has also spurred the use of standards. Production and supply chain is diligently managed so that it can meet its customer demand well on time. Toy cars planes etc.

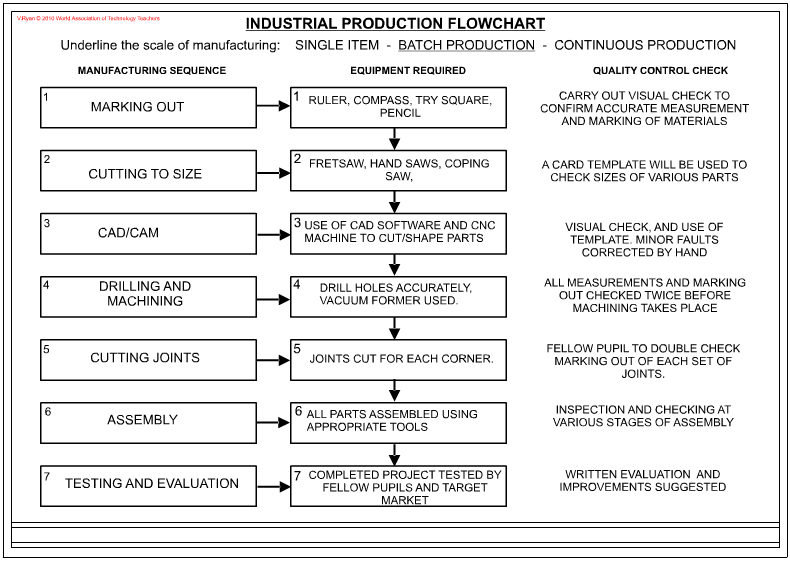

By the time the first cars appeared the bicycle was accepted as a valuable means of personal transport Companies like Peugeot in France and Humber and Riley in. In real practice these phases may overlap and many tasks are done in parallel concurrent engineering to streamline and maximize resource utilization. This product is so special that once you start using it you will understand the way it works quick and will never need any other software for the purpose of creating all mentioned above to see as a result incredible smart professional sophisticated.

41 New manufacturing system decision making. New Concept in Automotive Manufacturing. Toyota developed its current standards 5 to 10 years ago.

Phase 5 - Production Launch Feedback Assessment and Corrective Action. Think of it as a protective layer before putting on actual paint. The car bodies are each 6 ft wide and the work carriers are the same width.

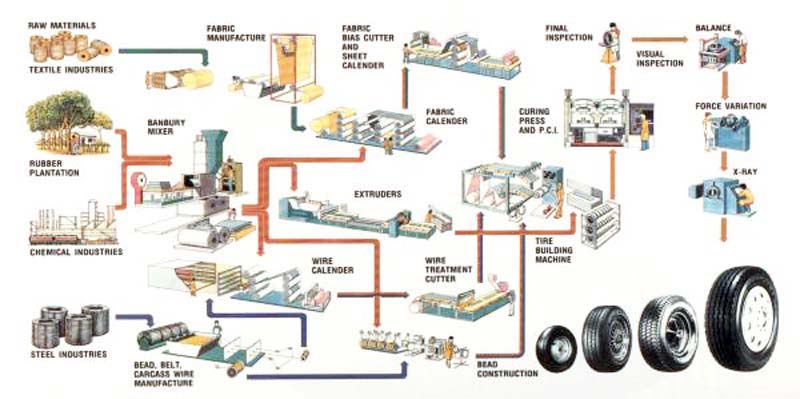

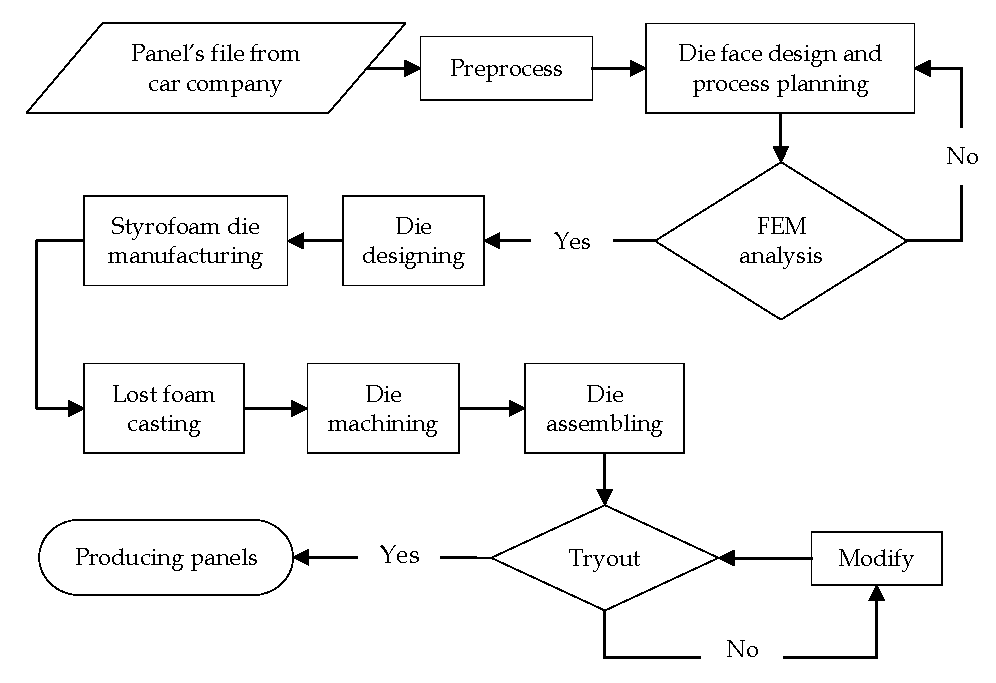

An intensive research and development are going on for alternate materials manufacturing processes and stamping tools for sheet-metal components with the main objectives of cutting down the weight and unit cost of the vehicle. MANUFACTURING PROCESS There are six basic processes in the manufacture of tires. The work that goes into building a physical model of a concept car is usually hidden behind closed doors known only to engineers sworn to secrecy and similarly tight-lipped subcontractors.

Although the general outline of the process is similar in current trials there are various options to carry out process steps during manufacturing of the CAR T cell product. After that it is time for the E-coat or the Electrophoretic Painting Process. The early stage of the current clinical trials mean that target cell numbers have not been established.

The first step in proposing a new manufacturin g process sequence and ultimately a. FPS provides plant level principles and metrics to achieve more efficient manufacturing operations and is the process behind plant design operation and evaluation. Steam boiler test To simulate the aging process the washdown sensors are placed in a steam boiler.

Mixing of carbon blacks elastomers and chemicals in the Banbury Mixer to form the rubber compounds. A large number of car companies evolved from bicycle manufacture. Ask anyone involved exactly which companies use 3-D printing technology to create concepts and the answer will invariably be many of them.

Simultaneously the steel content of the car is falling with the use of aluminium and new materials such as plastics. Casting is also heavily used in the toy industry to make parts eg. Tyre Manufacturing Process 41 Compounding and Banbury mixing 9 42 Milling 10 43 Extruding and Calendering 11 44 Component Assembly and Building 11 45 Curing and Vulcanizing 12 46 Inspection and Finishing 13 5.

Produce CAR T cells for larger numbers of patients. Todays cars are primarily sourced out to produce various sub-assemblies in over 4000 disparate locations as far away as China. This means a cars production plant is an active assembly point where skilled.

Then the car is cleaned to make sure theres no debris that might cause discomfort or damage the car. Omar Clemson University-International Centre for Automotive Research CU-ICAR USA 1. Process of turning corner in which is continued with the wheels ability bearing the moment in the rotary fatigue test 9.

The book would be useful as a core-course to BTech. This is recognisable by a change in the sensing range. To understand the car manufacturing process you have to understand the underlying supply chain that drives domestic vehicle assembly.

New concepts in automotive manufacturing. Storage buffers are included at various locations in the sequence of work flow. Calendering the fabrics and steel cord and coating them with rubber.

Therefore the scale of the process is still not defined. The book is intended for engineers of any specialization to present an overview of manufacturing process and the material used in it. A System-based Manufacturing Mohammad A.

The test simulates whether penetrating water molecules can disturb the sensor behaviour. The cars themselves are each 16 ft long and they must be separated by 9 ft. The book is considered to be useful universally specially in view of syllabus of.

The company strategies are well supported through comprehensive production process so that it can manage cost efficiency drive better quality output vehicles and to manage the high class operational environment. 2 describes the rationale how. Manufacturing techniques followed among the early automakers were similar to those used in other engineering industries.

Dot-h-805573 hfc i ab a34 no. They provide the automobile assembly plant with a way of dealing with a number of production. The process can be applied on metals and plastics The term casting is commonly used for metals and the term molding is used for plastics Examples.

Car Manufacturing Flowchart Template Google Docs Word Apple Pages Pdf Template Net

Automobile Manufacturing Process Flow Chart Hd Png Download Transparent Png Image Pngitem

Manufacturing Process Steel Sheets Products Nippon Steel Corporation

Car Manufacturing Process Pdf Leaflasopa

Manufacturing Process Steel Sheets Products Nippon Steel Corporation

The Automotive Body Manufacturing Systems And Processes Pdf Free Download Free Ebooks Pdf Manual Notes And Template Download

Flowchart Manufacturing Process Process Flow Chart Process Flow Chart Template Flow Chart

Design For Automotive Panels Supported By An Expert System Intechopen

Product Life Cycle How This Influences Car Design And Manufacture Environmental Factors

Pdf Process Design And System Layout For An Automobile Manufacturing And Assembly Plant

Materials Used In Automotive Manufacture And Material Selection Using Ashby Charts